The embedded sector is riding out some of the fiercest headwinds in memory. Inflation bites into margins. Tariffs add unpredictability to every supply chain conversation. Sourcing chips can still feel like a lottery. Deadlines bend around unpredictable hardware cycles. Yet surprisingly, many technical leaders still don’t see how much greater these market challenges become when paired with outdated embedded software practices. Business as usual? If only things were that simple.

When volatility is everywhere, a sluggish embedded lifecycle isn’t just an inconvenience—it’s fuel for the fire.

Budgets Are Tight—and Embedded Loses Out

Across manufacturing-heavy industries, there’s a familiar refrain: “Make do with less.” R&D budgets have dried up, especially for long-horizon device or hardware bets. Product managers tasked with launching new features and supporting legacy systems simultaneously are typically given trade-offs rather than additional resources. Meanwhile, cloud migrations and flashy analytics projects capture whatever new capital remains. Embedded roadmaps gather dust.

What does this mean for teams? It means more corners get cut. Technical debt swells. Schedules slip. Small cracks appear in the process—especially around test, regression, and traceability—suddenly threatening an entire product line.

Hardware Delays Turn into Vicious Cycles

Chip shortages may no longer dominate the news, but the echoes linger. Shortages, uncertain lead times, and forced redesigns have taught teams to expect the unexpected. Embedded projects tied to a stalled hardware cycle often enter a strange limbo: teams keep old hardware alive with makeshift code patches, while the clock keeps ticking. By the time the hardware arrives, tribal knowledge is lost, and what was once a small management challenge now looks like a full-blown crisis.

When Everyday Problems Become Business Risks

Legacy pain points—manual testing, “it works on my machine,” and one-off build scripts—weren’t just frustrating before, they were quietly expensive. Now, they’re multiplying every hit from market volatility. A firmware bug can stall a product launch or trigger a recall, costing far more than a few late nights. Delays in build reproducibility cascade: certification gets missed, a big customer walks, and the opportunity disappears. What’s really at stake isn’t just the next quarter, but reputation and market position for years to come.

Talent Drain and the Challenge of Retention

What sets embedded apart is the unique blend of system-level expertise and real-world field experience required to ship robust firmware. But with staff stretched thin and limited professional development, retaining your best engineers grows harder. Many move toward organizations that invest in processes, tools, and automation—places where they can build, not just patch. Every resignation pushes a team deeper into reactive mode, heightening dependence on those who remain.

Why “Just Hang On” No Longer Works

Project managers and technical leaders used to believe another sprint, a Red Bull-fueled push, or “one more fix” would get their teams through the crunch. That’s a fantasy in today’s environment. With risk and uncertainty baked into nearly every project input, the old tactics do little more than escalate the stakes. Sometimes an unnoticed test break or fragile integration becomes a national news story, a public safety issue, or a line in a C-suite resignation letter. Those who move past fire drills and toward modernization now are positioning themselves—and their teams—for recovery and growth when conditions improve.

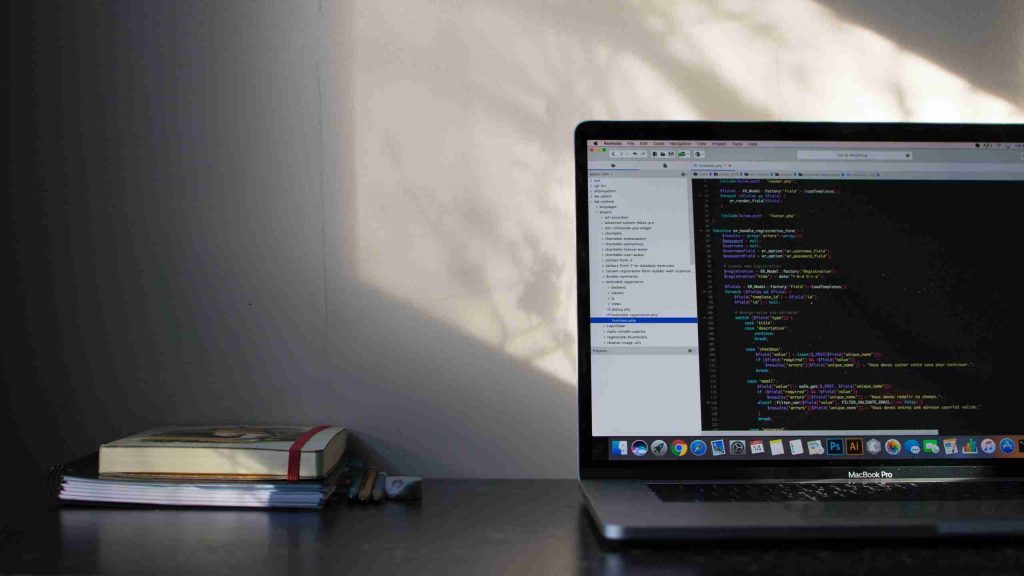

Real Modernization, Not Lip Service

- Build environments that prioritize consistency can stop surprises dead in their tracks, even when half the team is remote or outages affect your providers.

- True automation—regression, on-target, and integration tests—means failures are caught early, not during frantic last-minute scrambles.

- Traceability links code, builds, requirements, and field incidents. When (not if) things go wrong, the answer is a few clicks away—not buried in someone’s half-remembered command line or chat history.

Some firms do this and are winning business. They’re onboarding new hardware within weeks, pulling in audits with confidence, and keeping engineers challenged and motivated.

Partnerships Over Heroics

No leadership seminar ever celebrated the manager who “kept the old Jenkins server alive another month.” The new badge of honor is knowing when and what to outsource—freeing internal talent to do what only they can. Modernization partners specialize in the grittier work of infrastructure, compliance, and foundational process overhaul. The best ones deliver predictability, resilience, and faster time to market.

What Actually Works—And Where to Start

- For those looking to move, forget “big bang” transformations. Instead:

- Start with a focused audit: Identify where technical debt is sabotaging quality or launch dates.

- Quantify the risks of delay: What’s a missed launch really cost? How many support tickets trace back to a shaky build?

- Prioritize modern pipeline work—CI/CD suited for embedded, modular artifact management, and deep test coverage.

- Build partnerships that take on foundational retooling so your team can reclaim bandwidth for product innovation.

- Reward the engineers who help future-proof your process, not just those who patch this week’s critical bug.

Lead or Lag—The Choice Is Now

Modernization isn’t a slogan or a slide in a quarterly report. It’s the difference between teams that get stuck forever looping old mistakes and those that weather market upheavals, keep shipping, and retain their best people. Those who invest in robust, resilient practices will control their destiny, not just survive. For tech leaders, the only real risk is hoping that yesterday’s embedded status quo will protect against tomorrow’s disruptions.

Leadership in embedded today means meeting turbulence with bold, concrete action—not just weathering the storm, but redefining what “normal” looks like tomorrow.

Next Steps

If you’d like to discuss having Dojo Five help you with your embedded project, you can book a call with our team. And if you’re a firmware engineer who works on devices, you should check out our EmbedOps platform.